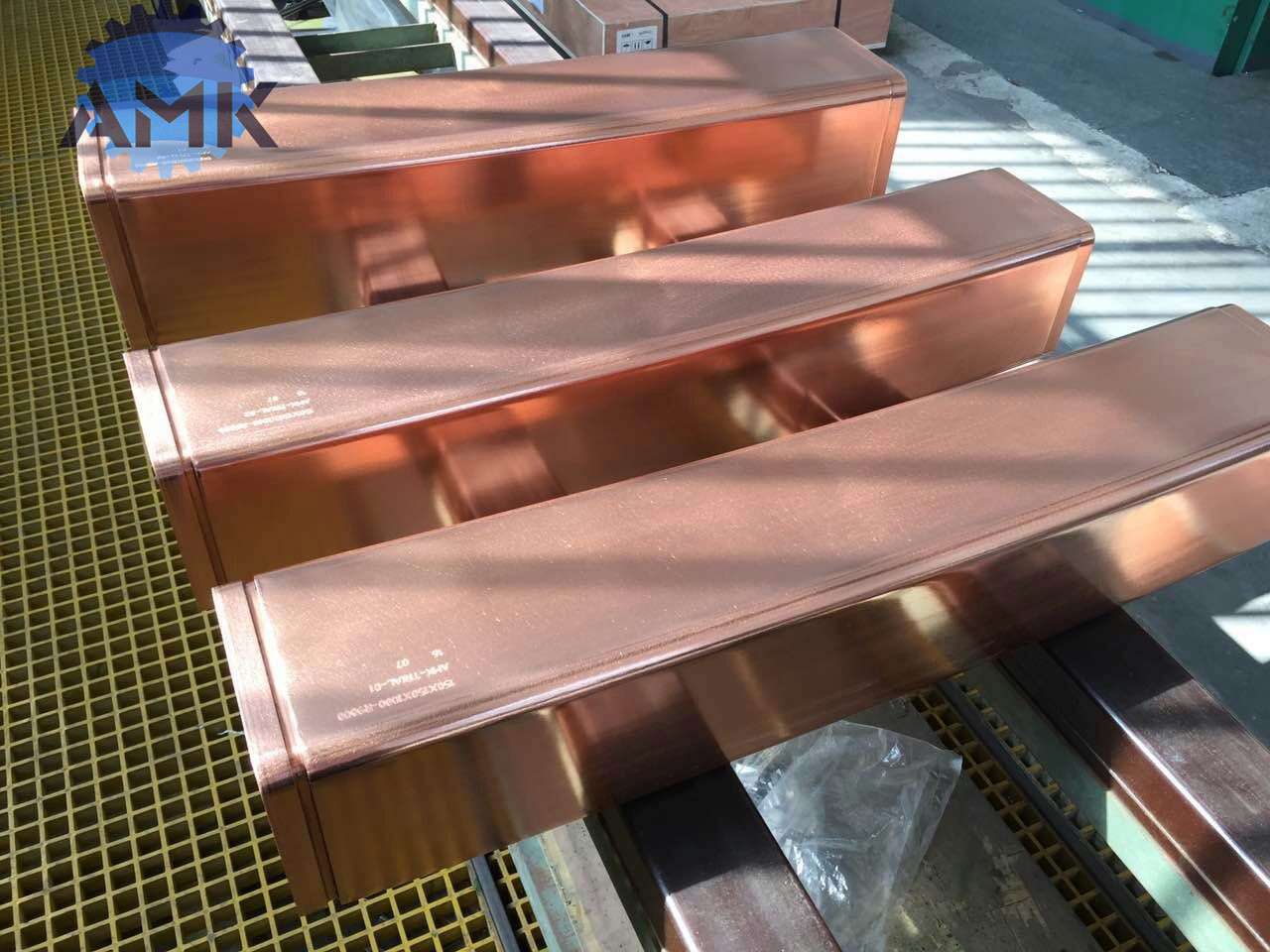

Materials of CCM Copper Mould Tube:

The materials of copper mould tubes should be the ones with good tensile

strength, fatigue strength, proper hardness, low elongation and high heat

conductivity coefficient. As a result, material like phosphorous deoxidize copper (CU-DHP) , Silver bearing (CUAG), CR-ZR-CU are widely accepted by users worldwide.

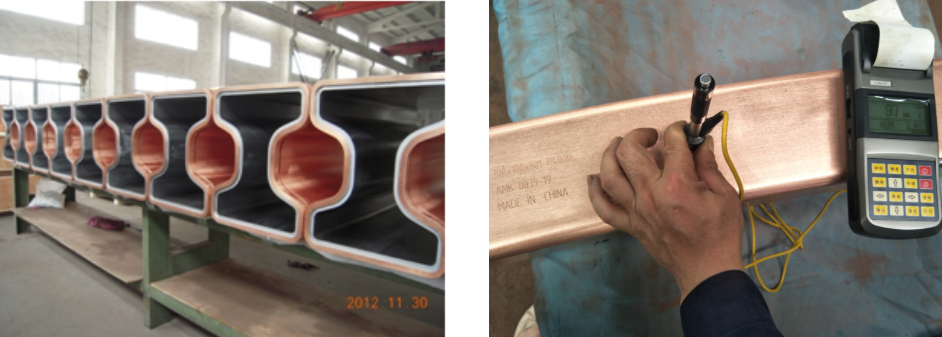

Coatings:

Copper has lower hardness which

leads to lower anti-abrasive property. Therefore, the area at the lower part of

the moulds, where the stress increases drastically due to shells, will be more

severely worn. To increase the life time of copper moulds, Uniform mould

interior surface plating with suitable hardness is needed. Most of the copper

mould tubes for small size billet casting are not used in any casting system

where there are rigid casting stream support, therefore they are very sensitive to

be worn. We use hard chrome plating to increase the life of mould tubes. The

plating thickness will be controlled in the best range. Based on our years of experience, we are able to provide Cr

coating, Ni-Cr coating, Ni-Fe coating to meet the various demands of customers both at home and abroad.

Notice:

1. Please use the copper mould tubes within one year.

2. Please store the copper mould tubes in someplace dry and well ventilated.

3. Keep the copper mould tubes away from acidic materials, especially the internal coating surface.

4. Polish the external surface of the copper mould tubes with sand paper if oxidized.

5. Pouring the molten steel to the center of the copper mould tubes

6. Avoid internal surface scratch of the moulds caused by manual operation.

AMK is specialized in producing and supplying metallurgical & mechanical equipments and spare parts for steel mill, rolling mill, ferroalloy industry, foundry,mineral processing industry etc.

NO.39-310 OF YONG KANG HARDWARE CENTER,JIANGYIN 214400,JIANGSU,CHINA

+86-510-86028707

18800511782(Whatsapp)

sales@amkgroup.cn